SoCalGas and Bloom Energy Collaborate on New Hydrogen Project

Project will provide long duration clean energy storage and resiliency

Dec 15, 2021

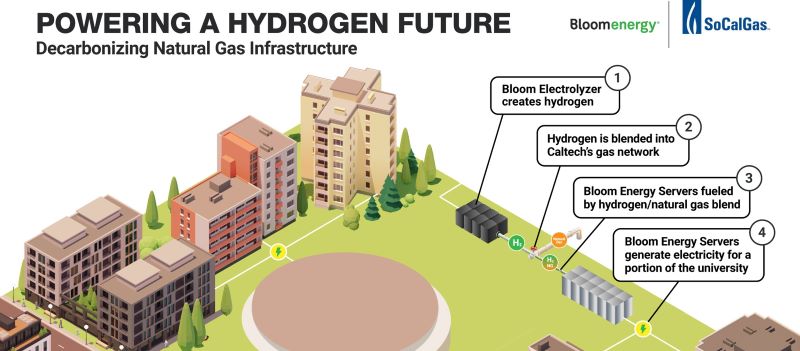

SoCalGas and Bloom Energy will work together on a project to showcase the future of the hydrogen economy and the technologies needed to help California reach carbon neutrality. The companies will collaborate to generate and then blend hydrogen into the existing natural gas network at California Institute of Technology (Caltech) in Pasadena to demonstrate how natural gas infrastructure can be decarbonized, while balancing future energy supply and demand. The project is set to launch next year.

The collaboration will utilize Bloom Energy’s solid oxide, high temperature electrolyzer to generate hydrogen, which will then be injected into Caltech’s natural gas infrastructure. The resulting 10 percent hydrogen blend will be converted into electricity without combustion through existing Bloom Energy fuel cells downstream of the SoCalGas meter, producing electricity for a portion of the university. For the purpose of this project, the electrolyzer is designed to generate hydrogen from grid electricity.

“California has ambitious climate goals and a successful energy transition will require companies to collaborate and implement innovative projects,” said California State Assembly member Chris Holden. “This unique demonstration could help our state transition to a carbon neutral future.”

Once widely adopted, the electrolyzer and fuel cell combination could enable long duration clean energy storage and low-carbon distributed power generation through the gas network for businesses, residential neighborhoods, and dense urban areas. When configured as a microgrid, it could also provide resilient power when and where energy is needed most, protecting businesses, campuses or neighborhoods from widespread power outages.

“We need to pursue a diverse set of decarbonization levers,” said Maryam Brown, president, SoCalGas. “Projects like this expand and accelerate clean fuel initiatives, which will help decarbonize California faster.”

Bloom’s high-temperature electrolyzer produces hydrogen more efficiently than low-temperature PEM and alkaline electrolyzers. Because it operates at high temperatures, the Bloom Electrolyzer requires less energy to break up water molecules and produce hydrogen. Electricity accounts for nearly 80 percent of the cost of hydrogen from electrolysis. By using less electricity, hydrogen production becomes more economical and will accelerate adoption. The Bloom Electrolyzer is also designed to produce green hydrogen from 100 percent renewable power.

“With our technology and collaborations like this one, Bloom Energy continues to lead advancements in decarbonizing today’s energy system and accelerating a hydrogen-fueled economy,” said Sharelynn Moore, executive vice president and chief marketing officer, Bloom Energy. “Enabling both the production and utilization of hydrogen, Bloom Energy’s solutions are well-suited to support use of the natural gas network to reduce carbon emissions while bolstering energy resilience.”